PROCESS CAPABILITIES

metal finishing services

Anodizing

Request Quote More Information

Request Quote More Information

Request Quote More Information

Request Quote More Information

Stainless Steel Passivation

Request Quote More Information

Chromate Conversion Coating

Request Quote More Information

Titanium Cleaning

With our 250 gallon solution and rinse tanks we are capable

of handling a multitude of part configurations to handle most, if not all, of

your titanium cleaning needs.

Obtained NADCAP certification to DU01-P4TF3 on January 30th 2020

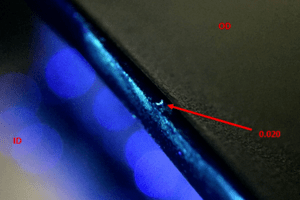

Nondestructive Testing

Our personnel have experience performing inspections in ALL penetrant methods so if you have specific requirements we may be able to accommodate that as well. All personnel are certified in accordance with NAS-410 which exceeds SNT-TC-1A requirements.

Request Quote More Information

Brown Precision, Inc.

About Us

The success of Brown Precision, Inc. has been based on three main principles – Quality, Integrity and Performance. We are a company known for our commitment to customer needs. This has been a prime objective for over 50 years. The next time you are looking for metal finishing services, we respectfully request that you consider Brown Precision, Inc.

Our History

BPI was founded in 1964 as a machine shop under the name of SEMCO, Inc., in a small industrial building (8,000 sq. ft.) located in Huntsville, AL. The business became a client of Mr. Roland E. Brown, CPA, in 1976.

In June 1992, his son Daniel T. Brown, BSME, 1992, from The University of Alabama in Huntsville (UAH), became company president. Over the next several years, Mr. Brown made large investments in the company. Greg Brown (his other son) joined the company in 1995, and he and Dan made very effective use of this investment in employee training and acquisition of state-of-the-art machinery.

Our Mission

Our mission is to be a world class contract manufacturer, a process-driven company from top to bottom, eliminating our customers’ risk by providing 100% on time delivery and uncompromising quality assurance.

Our customers come back to us repeatedly for their needs, a fact we’re very proud of. Our focus centers on the concept of timely response to your manufacturing needs. We back up our promise of customer satisfaction with equipment, skills, responsiveness and dedicated Account Managers ensuring customer’s needs are met and expectations are exceeded.

For more information about us, visit brownprecisioninc.com

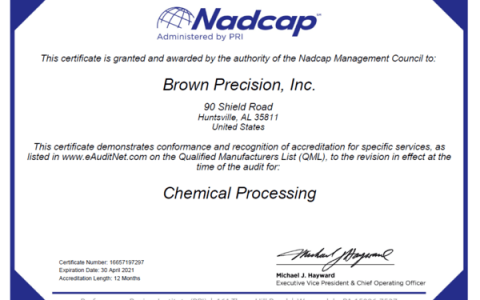

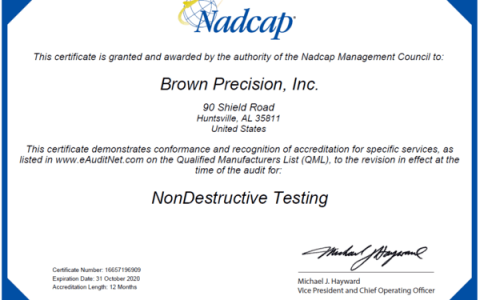

Quality Certifications

Being NADCAP certified at our Huntsville, AL facility allows us to expand our penetrant portfolio to meet more customer requirements. We began performing penetrant inspections at Brown Precision in January of 2018. We received our GE Certification on July 9th 2018 and our NADCAP certification on July 26th 2019. We are currently certified to perform inspections in accordance with GE specifications P3TF47 and P3TF2.

Titles:

Chemical Processing:

Titanium Cleaning – Alkaline

NonDestructive Testing:

Penetrant Testing

Contact

Request Quote

Use our form to request a quote, a contact, or information on our upcoming and new capabilities and services.

Addresses

Atmore

AL 36502

United States

90 Shields Rd

Huntsville

AL 35811

United States